By using a combination of cameras and computers, machine vision systems can accurately and real-time detect and determine the quality of printed materials, including image clarity, color accuracy, and printing position. The introduction of machine vision technology not only improves production efficiency and quality stability in the printing industry but also reduces the cost of manual inspection and the risk of subjective judgment. Additionally, machine vision systems can provide real-time alerts and detailed analysis reports, assisting printing companies in achieving quality analysis, tracking, and management, thus further enhancing the quality of printed materials and customer satisfaction.

1. Fatigue: Manual inspection is prone to unstable quality when performed under fatigue.

2. Subjectivity: Manual inspection is difficult to achieve consistent results due to subjective factors that can affect judgment.

3. Vulnerability to interference: Manual inspection is susceptible to interference from emotions and characteristics of printed materials, leading to misjudgment or missed defects.

4. High cost: Manual inspection requires a large number of personnel, resulting in increasing labor costs.

5. Slow speed: Manual inspection is relatively slow and cannot meet the demands of high-efficiency production.

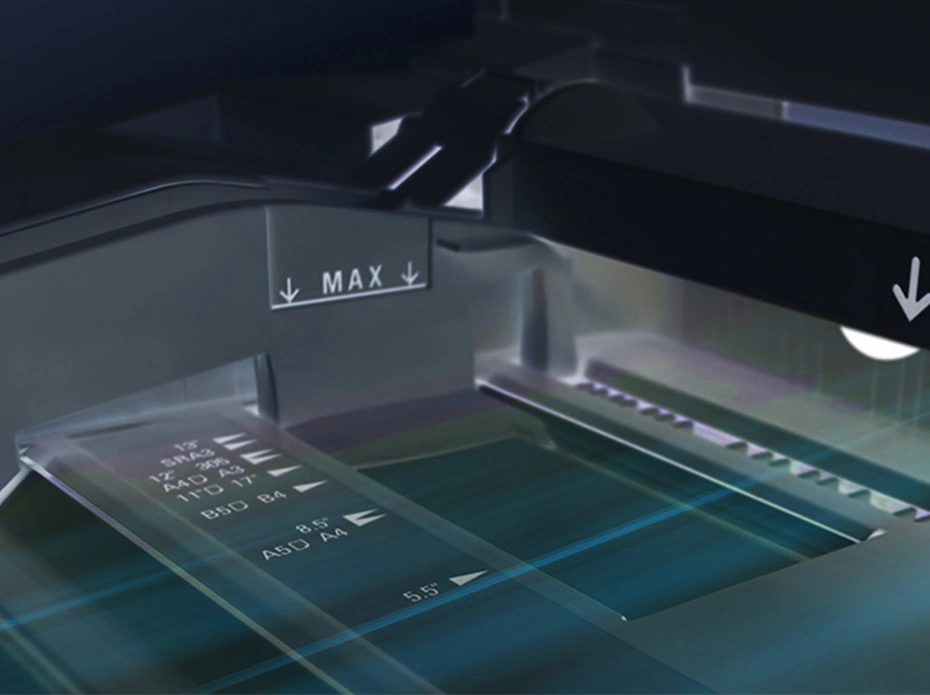

Machine vision - replacing human eyes with cameras and human brain with computers. The working principle of machine vision in printing and packaging quality inspection is relatively simple. It involves capturing images of printed materials using cameras and comparing them with standard images. If differences are found that exceed the set tolerance range, the products are deemed as non-compliant. However, actual machine vision systems are much more complex.

1. Online and offline inspection: Machine vision inspection systems can be categorized into online and offline inspection based on their installation locations. Online inspection systems are installed on printing equipment to monitor print quality in real-time, while offline inspection systems are installed on sample inspection machines or rewinding machines with sorting capabilities, automatically separating good and defective products into different compartments based on the inspection results.

2. Quality analysis, tracking, and management: Adopting machine vision equipment for quality inspection enables real-time alerts and comprehensive analysis reports. Operators can address issues during the production process based on real-time alerts and analysis reports, while managers can track and manage the production process using the analysis reports. High-quality machine vision inspection equipment goes beyond detecting good and defective printed materials, as it also possesses post-analysis capabilities. Through quality analysis using industrial machine vision, manufacturers can improve process workflows, establish quality management systems, and achieve long-term quality standards.

Keywords:

1. Machine vision

2. Online inspection and offline inspection

3. Quality analysis, tracking, and management

4. Real-time alerts